Luga-Bar

PURPOSE

Luga-Baris mono-layer artificial casing intended for manufacturing of all kinds of frankfurters, wieners and mini-sausages.

COMPOSITION

Luga-Bar casing is produced according to up-to-date technology by co-extrusion method, of high quality polyamide raw materials manufactured by leading polymer producers. All raw materials are certified for contact with foodstuffs.

ASSORTIMENT

Luga-Bar casing is divided info the following types:

|

Types of casing |

Length of casing in one roll, m |

Nominal caliber, mm |

Characteristics |

|

Luga-Bar |

1500 |

16-36 |

Using on any automatic and semi-automatic lines |

|

Luga-Bar M |

1500 |

||

|

The casing has big stuffing capacity, the line is recommended to use is semi-automatic |

Shirred casing Luga-Bar

|

Nominal caliber, mm |

Type of casing |

Type of shirring |

Dimensions of shirred (max) briquette, mm |

Length of casing in shirred briquette, m |

Length of casing in packing box * , m |

Quantity of packing boxes in one shipping box, pieces. |

Length of casing in one shipping box * , m |

Gross weight, max, kg |

||

|

Length of briquette

|

External diameter of briquette (max) |

Inner diameter of briquette (min) |

||||||||

|

16 |

А,P |

rigid |

245 |

18,0 |

9,5 |

25,0 |

1400 |

6 |

8400 |

12,0 |

|

17 |

19,0 |

10,5 |

25,0 |

1200 |

7200 |

12,0 |

||||

|

18 |

20,0 |

10,5 |

25,0 |

1050 |

6300 |

12,0 |

||||

|

19 |

21,0 |

11,5 |

30,0 |

1260 |

7560 |

12,5 |

||||

|

20 |

22,0 |

11,5 |

33,34 |

1167 |

7002 |

13,5 |

||||

|

21 |

24,0 |

12,5 |

33,34 |

1000 |

6000 |

11,5 |

||||

|

22 |

25,0 |

12,5 |

33,34 |

1000 |

6000 |

12,5 |

||||

|

23 |

26,0 |

13,6 |

35,8 |

1000 |

6000 |

12,5 |

||||

|

24 |

27,0 |

13,6 |

35,8 |

895 |

5370 |

12,0 |

||||

|

26 |

29,0 |

13,6 |

35,8 |

716 |

4296 |

12,0 |

||||

|

28 |

31,0 |

18,0 |

30,0 |

540 |

3240 |

9,0 |

||||

|

29 |

32,0 |

18,0 |

30,0 |

540 |

3240 |

9,5 |

||||

|

30 |

34,0 |

18,0 |

33,34 |

600 |

3600 |

12,0 |

||||

|

32 |

35,0 |

22,0 |

33,34 |

467 |

2800 |

10,0 |

||||

|

34 |

37,0 |

22,0 |

33,34 |

467 |

2800 |

11,0 |

||||

|

36 |

39,0 |

22,0 |

33,34 |

400 |

2400 |

11,0 |

||||

Luga-Bar casing in rolls

|

Nominal caliber, mm |

Length of casing in one roll, m |

Quantity of rolls in one shipping box, pieces |

Length of casing in one shipping* box, m |

|

16 - 26 |

1500 |

5 |

7500 |

|

28 - 36 |

4 |

6000 |

* – dimensions of shipping box (length хwidth хheight), mm 314х314х410

Colours of Luga-Bar casing

|

№ |

Colour |

Code |

|

|

1 |

Red |

2.0 |

|

|

2 |

Pink |

2.5 |

|

|

3 |

Orange |

3.0 |

|

|

4 |

Gold |

5.1 |

|

|

5 |

Bronze |

7.0 |

|

|

6 |

Transparent |

8.0 |

|

|

7 |

Smoke shades |

Caramel |

9.1 |

|

8 |

Salmon |

9.3 |

|

|

9 |

Terracotta |

9.5 |

|

Casing can be printed onto one or both sides. Paints used for printing are permitted to contact with food and they are resistant to mechanic action, fat and boiling.

Quantity of printed colors – from 1 up to 5. Full-color printing is available.

PROPERTIES AND ADVANTAGES

1. High barrier properties.

Luga-Bar casing possesses ten times lower permeability to oxygen and vapor, in comparison to collagen and cellulose casing. It brings following advantages:

-

Minimal losses during thermal treatment and storage of frankfurters and wieners..

-

Prolonged shelf of frankfurters and wieners. Shelf life of final products packed in polyamide casing Luga-Bar is 20 days. This term approved by Ukrainian and Russian Ministries of Health.

-

Attractive appearance of final product during whole period of shelf life.

2. Excellent physic mechanical properties.

-

Allow to use Luga-Bar casing with all types of stuffing equipment.

-

Provide efficient production of stuffing equipment.

-

Permit to overstuff the casing for increasing profitability of production.

3. Caliber stability.

Caliber stability of Luga-Bar casing provides excellent functioning of automatic and semi-automatic equipment and allows to plan casing consumption.

4. High level of thermo-shrinkage.

Thermo-shrinkage properties ofLuga-Bar casing is the best preventer against forming of fat and gel pockets as well as wrinkles, and they give organoleptic properties to final products.

5. High level of thermo-shrinkage.

Casing is resistant not only to high temperature, but also to its lasting effect. That is why the range of thermal treatment of frankfurters and wieners in Luga-Bar casing is wider, in comparison with natural, cellulose and collagen casing.

6. Biological inactivity.

Polymeric materials used for production of Luga-Bar casing are inert to bacteria and moulds. This property improves hygienic characteristics of casing and sausage production as well.

PREPARATION OF THE CASING

Correct casing soaking provides regular stuffing with recommended stuffing diameter.

Luga-Bar casing should be soaked in cold water at temperature 15-20°Сin the following way:

-

Sections of casing– 30-40 minutes;

-

Briquettes of rigid shirring, type "А"and"P"– should be submerged completely into cold water for 30-40 minutes;

-

Briquettes of rigid shirring type "А" could be used without any soaking before-hand.

Correct soaking gives to the casing additional elasticity, coupled with high durability, that makes easy manual stuffing process as well as stuffing at automatic equipment.

It is forbidden:

-

To soak casing in warm or hot water.

-

To soak repeatedly once soaked, but unused casing.

MEAT STUFF COMPOSITION

As Luga-Bar casing is impermeable to gas, vapor and moisture, so when preparing the stuff it is recommended to lower quantity of water by 5-10 % in comparison to norm for natural and cellulose casing. More precise needed quantity of water can be determined by accounting of kind and characteristic of meat (ratio of flash to flat), rate of overstuffing, type and amount of stabilizing, binding, emulsifying and preserving ingredients, adjusting of stuffing equipment, etc. Practice shows that in spite of water quantity lowering, output of final product does not lessen.

STUFFING

Puncture either of casing itself or onto product is forbidden.

RECOMMENDATIONS ON STUFFING TECHNOLOGY OF LUGA-BAR CASING

|

Nominal diameter of casing, mm |

Stuffing diameter, mm Luga-Bar |

Stuffing diameter, mm Luga-Bar M |

Outer diameter of stuffing horn, mm |

№ of plastic chuck |

||

|

min |

max |

min |

max |

Frank-A-Matiс |

||

|

16 |

17,0 |

17,5 |

17,5 |

18,5 |

8 |

17 |

|

17 |

18,0 |

18,5 |

18,5 |

19,5 |

8 |

17 |

|

18 |

19,0 |

19,5 |

19,5 |

20,5 |

8-9 |

17-18 |

|

19 |

20,0 |

20,5 |

20,5 |

21,5 |

9-10 |

18-19 |

|

20 |

21,0 |

21,5 |

21,5 |

22,5 |

10 |

19-20 |

|

21 |

22,0 |

22,5 |

22,5 |

23,5 |

11-12 |

20-21 |

|

22 |

23,0 |

23,5 |

23,5 |

24,5 |

11-12 |

21-22 |

|

23 |

24,0 |

24,5 |

24,5 |

25,5 |

12-13 |

22-23 |

|

24 |

25,0 |

25,5 |

25,5 |

26,5 |

12-13 |

23-24 |

|

26 |

27,0 |

27,5 |

27,5 |

28,5 |

12-13 |

28 |

|

28 |

29,0 |

29,5 |

29,5 |

30,5 |

14-16 |

28-29 |

|

29 |

30,5 |

31,0 |

31,0 |

32,0 |

14-16 |

29 |

|

30 |

31,5 |

32,0 |

32,0 |

33,0 |

14-16 |

29 |

|

32 |

33,5 |

34,0 |

34,0 |

35,0 |

14-16 |

29 |

|

34 |

35,5 |

36,0 |

36,0 |

37,0 |

||

|

36 |

37,5 |

38,0 |

38,0 |

39,0 |

||

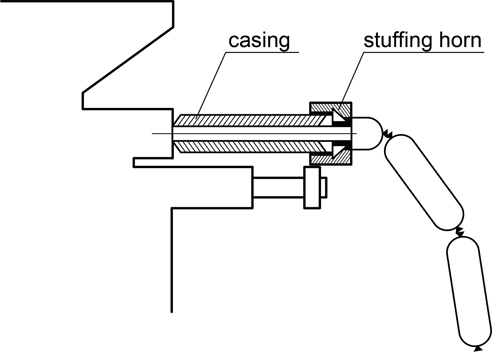

SHEME OF PLACING LUGA-BAR M BRIQUETTES IN SEMI-AUTOMATIC STUFFERS WITH TWISTER BL° CK

THERMALTREATMENT

Thermal treatment of product in Luga-Bar casing does not differ from one covered by similar casing and can be conducted by traditional technology.

As Luga-Bar casing is practically impermeable for gas, so product packed into it should not be exposed to real smoking. Taste of smoking can be reached by addition into stuff of ingredients giving peculiar aroma of final product. For this purpose smoking shades of Luga-Bar casing were developed too.

Conditions of thermal treatment should be determined by producer depending on equipment used for production.

Drying stage could be excluded, but boiling should be made with step-by-step temperature increasing. Abrupt temperature increasing can lead to stuff emulsion exfoliation, color irregularity of final product and physical defects of the casing.

RECOMMENDED TECHNOLOGY OF THERMAL TREATMENT

method 1

CURING→STEAM HEATING→BOILING →SHOWERING→COOLING

- CURING – for 1.5-2 hours at 0...4°Сin curing chamber.

- STEAM HEATING – 15 minutes at 40°Сand 100% relative humidity, at 60°Сand relative humidity 100% until getting 47°Сin centre of the stick.

- BOILING – approximately 10-15 minutes at 76-80°Сand 100% relative humidity until getting 72°Сin the centre of the stick.

- SHOWERING - COOLING: after thermal treatment, frankfurters and wieners should be intensively cooled by cold water until getting +25…+30°Сin the center of the stick. Cooling by cold air or draft influence is inadvisable – it can lead to wrinkles forming. Final products should be placed in refrigerator at +4…+6°Сuntil delivery to a customer.

method 2

CURING→STEAM HEATING→BOILING →SHOWERING→COOLING

- CURING – for 1.5-2 hours at 0...4°Сin curing chamber.

- DRYING (in three stages) – for 15 minutes at 50°Сand 30% relative humidity, for 25 minutes at 60°Сand 30% relative humidity, for 15 minutes utes at 70°Сand 30% relative humidity.

- BOILING – approximately 10-15 minutes at 76-80°Сand 100% relative humidity until getting 72°Сin the centre of the stick.

- SHOWERING - COOLING: after thermal treatment, frankfurters and wieners should be intensively cooled by cold water until getting +25…+30°Сin the center of the stick. Cooling by cold air or draft influence is inadvisable – it can lead to wrinkles forming. Final products should be placed in refrigerator at +4…+6°Сuntil delivery to a customer.

|

Situation |

Reason |

Recommendations |

|

Greasy surface |

Exceeding temperature of thermal treatment |

Lower the temperature |

|

Fat and gel pockets |

Low indexes of meat stuff moisture binding properties |

Apply technological methods of moisture binding increasing and/or lower quantity of water |

|

Under-stuffing |

Increase stuffing diameter to recommended |

|

|

Exceeding temperature of thermal treatment |

Lower the temperature |

|

|

Pale color |

Wrong temperature and humidity level during thermal treatment |

Adjust to required |

|

Non-uni-form color |

Non-uniform temperature and relative humidity in space of thermal chamber |

Adjust to uniform |

|

Wrinkles |

Exceeding air circulation in thermal chamber |

Lower to required |

|

Under-stuffing |

Increase to recommended stuffing diameter |

|

|

Exceeded quantity of moisture in stuff |

Lower to required |

|

|

Non-dense outer layer of product |

Exceeding temperature and relative humidity while intensive heat treatment |

Lower to required |

|

Low output of final product |

Wrong quantity of water in meat stuff |

Correct meat stuff composition |

|

Wrong temperature in regimes of thermal treatment |

Correct the temperature in each stage of thermal treatment |

|

|

Wrong circulation and/or humidity of air in treatment chambers |

Correct to required |

|

|

Error in measuring of humidity |

Maintain meter of humidity |

|

Situation |

Reason |

Recommendations |

|

Casing is winding onto stuffing horn |

Wear and tear of twister plastic chuck |

Replace the chuck |

|

Stuffing horn is bent |

Replace or straighten stuffing horn |

|

|

No centering of stuffing horn to twister |

Get centered |

|

|

Stuffing horn is stained by something |

Fix and delete the source of staining |

|

|

Abnormal pressure |

Adjust pressure to norm |

|

|

Rupture |

Burrs on TPC, LC, stuffing horn, etc. |

File the burrs off |

|

Exceeding of recommended stuffing diameter |

Adjust stuffing, lower speed |

|

|

Wrong choice of size of TPC |

Replace the TPC |

|

|

Wrong adjusting of linker chain |

Adjust linker chain correctly |

|

|

TBRR too squeezed |

Adjust friction |

|

|

Wrong choice of linker chain |

Replace linker chain |

|

|

Rupture of casing after stuffing |

||

|

1. Repeated ruptures in the beginning of twisting |

Wrong choice of size of TPC |

Replace to correct one |

|

No centering of shirred of briquette |

Get centered |

|

|

Burrs on stuffing horn |

File the burrs off |

|

|

2. Repeated ruptures in the middle of twisting |

Stuffing horn is bent |

Replace or straighten it |

|

3. Repeated ruptures in the end of twisting |

Wrong choice of size of stuffing horn |

Replace to right one |

|

Burrs on stuffing horn |

File the burrs off |

|

|

Wobbling of stuffing horn |

Replace stuffing horn or adjust feeding support or replace the whole worn of stuffing horn |

|

|

4. Repeated ruptures in the same area on body of frankfurter |

Burrs in some part of machine |

Check the whole technological stream, find the burrs and file them off |

|

5. The only one rupture on length of linker chain |

Bad chain |

Replace it |

|

6. Random ruptures |

Bending in stuffing horn |

Replace or straighten it |

|

Exceeding size of stuffing horn |

Replace to right one |

|

|

Too tight position of casing in TPC |

Loosen the friction in TPC or replace it to another with bigger diameter |

|

|

Defect in twister plastic chuck |

Replace to another |

|

|

Exceeding overstuffing |

Lower to recommended stuffing diameter |

|

|

Exceeding pressure |

Adjust to normal |

|

|

Burrs somewhere in machine |

Find and file them |

|

|

|

||

|

Rupture at closed end |

Worn or too small twister plastic bush |

Replace it |

|

Too tight position of casing in TPC |

Loosen the friction in TPC or replace it to another with bigger diameter |

|

|

Exceeding pressure |

Adjust to normal |

|

|

Bending in stuffing horn |

Replace or straighten it |

|

|

Closed end winding onto linker chain |

Fault in pump |

Check and fix it |

|

Too tight position of casing in TPC |

Loosen the friction in TPC or replace it to another with bigger diameter |

|

|

Wrong twisting – exceeding or not enough |

Incorrect speed of twister |

Adjust to required |

|

Too tight position of casing in TPC |

Loosen the friction on TPC or replace it to another with bigger diameter |

|

|

End of frankfurter is not filled with stuff |

Too short motion of feeling lever |

Increase to required |

|

Different mass of frankfurters |

Linker chain is not adjusted |

Adjust |

|

Defect in doser pump |

Fix or replace |

|

|

Under-stuffing, exceeding over-stuffing |

Adjust to recommended stuffing diameter |

|

|

Random length of frankfurters |

Wrong size of twister plastic chuck |

Replace to right one |

|

Wrong choice or adjusting of linker chain |

Replace or adjust |

|

|

High-speed modes |

Reduce the rate of forming |

|

|

Fault in block of feeding lever |

Fix |

|

|

Rupture of twisting segment before thermic treatment |

Defect in linker chain |

Fix |

|

Burrs in conveyer or frame |

Fix |

|